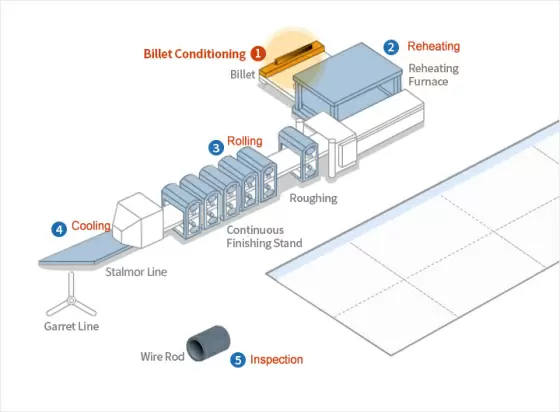

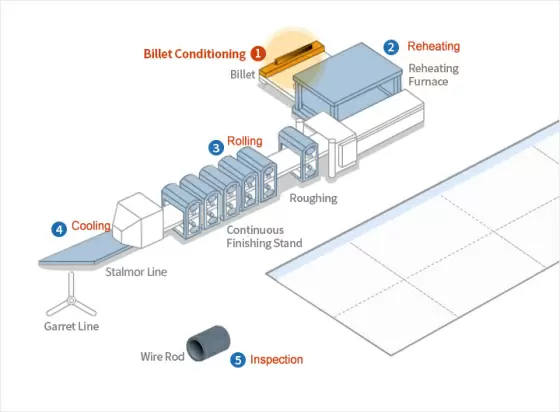

Wire Rod

Wire Rod 1. Billet Conditioning: This process is intended for checking the surface quality of billet and removing any defects. Shot blast is used to remove

Our company is committed to producing steel products of the highest quality.We employ advanced technologies and equipment to ensure the consistency and reliability of our products.

Wire Rod 1. Billet Conditioning: This process is intended for checking the surface quality of billet and removing any defects. Shot blast is used to remove

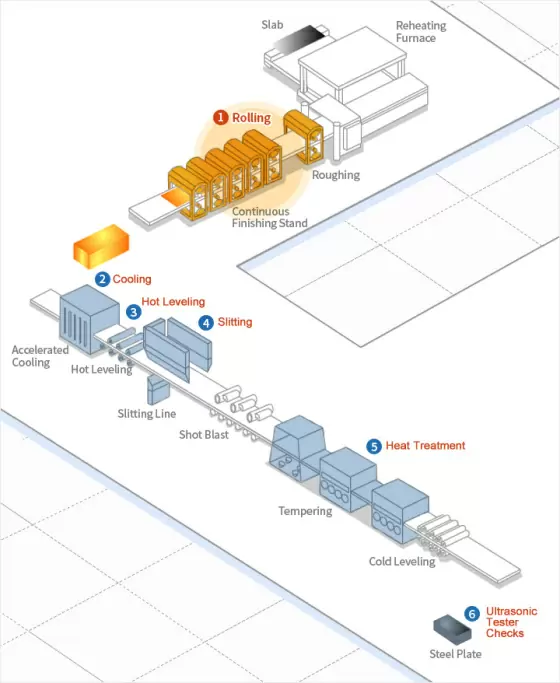

Steel Plate 1. Rolling: The 4-high reversible finishing mill with the maximum load of 7000 tons minimizes internal defects even inly thick plates. Automatic gauge control

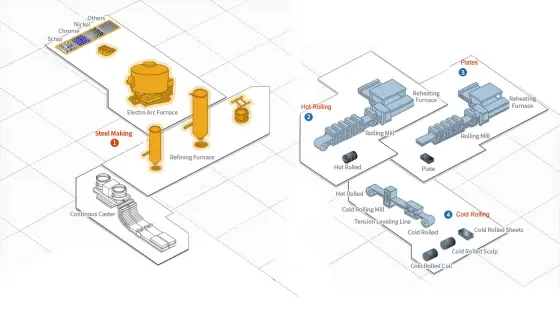

Stainless Steel 1. Steel Making: Steelmaking has the greatest impact on the quality and cost of steel products. We has state-of-the-art AOD, VOD and continuous casting

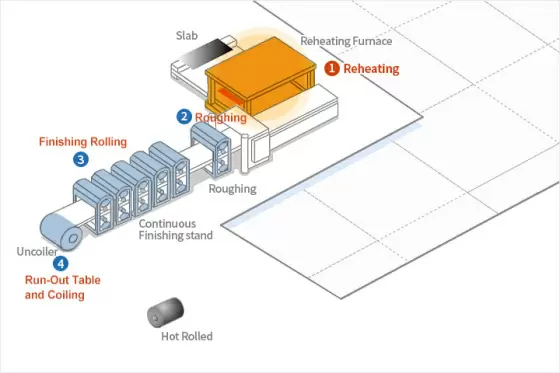

Hot Rolled Steel 1. Reheating: Hot rolled coils pass through a pickling line, where scale breaker machines and hydrochloric acid solutions are used to remove any

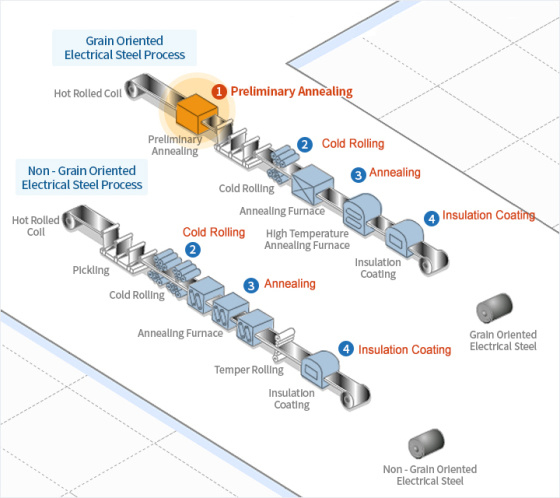

Electrical steel 1. Preliminary Annealing: During the preliminary annealing process, a scale which may have formed on the hot rolled steel is removed as delayed passing

Cold Rolled Steel 1. Pickling: Hot rolled coils pass through a pickling line, where scale breaker machines and hydrochloric acid solutions are used to remove any

No matter what your needs are, please contact us and we will answer them for you one by one.

JOIN INDUSTRIAL CO., LIMITED has 14+ years in metal processing, offering carbon steel, stainless steel, galvanized, and color-coated products. We focus on integrity, quality, and customer-first service, driven by a skilled team and advanced equipment.

© Copyright 2024 JOIN INDUSTRIAL CO., LTD

Designed by AdmarV